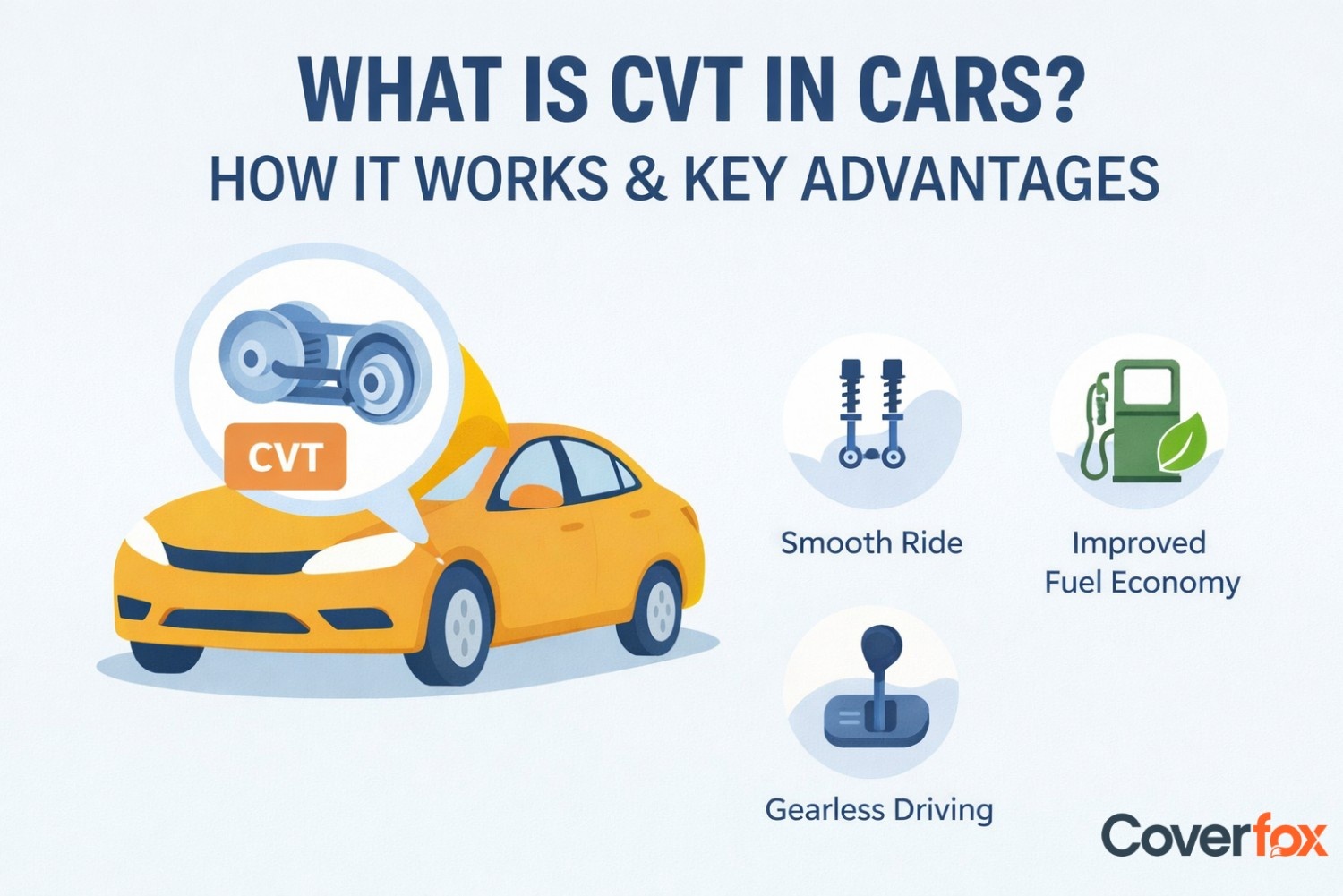

The CVT (Continuously Variable Transmission) is an automatic gearbox that provides seamless gear changes using pulleys and a belt or chain. Common in modern fuel-efficient cars, it offers smooth acceleration, better mileage, and lower emissions. While CVTs improve comfort and efficiency, they have limitations like the rubber-band feel and higher repair costs, which proper maintenance can help reduce.

The CVT, abbreviated "Continuously Variable Transmission", is a type of automatic gearbox that varies gear ratios continuously without setting steps. The system is used in most modern vehicles, especially fuel-efficient vehicles in India. Knowledge of CVT transmission features helps policyholders decide on car insurance online, since repairs to different transmissions cost differently.

How a CVT Transmission Works in Cars?

A CVT transmission functions with the help of a belt or a chain that is located between two variable-diameter pulleys attached to the engine and wheels. The pulleys vary in width when the accelerator is depressed: one of them becomes narrower, and the other becomes wider, and the gear ratio is varied continuously. This maintains the engine at an optimum RPM of power or efficiency without apparent changes.

A continuously variable transmission has an infinite number of ratios to choose from, unlike traditional automatics, which have fixed gears. Throttle input, vehicle speed, and load sensors are used to adjust the positions of pulleys either hydraulically or electronically. Power is transferred to the drive wheels without any hiccups in the engine, and this makes movement in traffic less jerky.

Components of CVT Transmission in Cars

The CVT has key components that allow it to be fully functional in the car:

Primary pulley:

Secondary pulley:

Steel belt or chain:

Hydraulic control unit:

Torque converter:

Connected directly to the engine, the primary (drive) pulley adjusts its diameter based on engine speed and throttle input. By expanding or contracting, it controls how much power is transmitted to the belt. This continuous adjustment enables smooth gear ratio changes without fixed shifts.

Attaches to the output shaft and adjusts the wheel's speed. It works in coordination with the primary pulley to vary the transmission ratio. As one pulley widens, the other narrows, maintaining optimal torque delivery and speed balance.

A high-strength steel belt or chain connects the two pulleys and transfers torque efficiently. It is designed to withstand high pressure while minimising slippage. Its flexibility allows continuous ratio variation instead of fixed gear steps.

This system uses fluid pressure to precisely adjust pulley positions. It responds to inputs from sensors and the engine control unit (ECU). Accurate hydraulic control ensures smooth acceleration and improved fuel efficiency.

Allows the vehicle to move from a complete stop without stalling. It provides initial torque multiplication during acceleration. In some modern CVTs, it may be replaced or supported by a start-up clutch for better efficiency.

These components combine to work with specific ratio adjustments, usually with engine computers, to achieve hybrid efficiency.

Different Types of CVT in Cars

Several CVT designs apply to different vehicles:

1. Push-belt CVT:

This is the most common type, using a steel push-belt running between variable pulleys. It delivers smooth and fuel-efficient performance, making it ideal for city cars and sedans like the Honda City. It balances affordability with everyday driving comfort.

2. Pull-chain CVT:

Instead of a push-belt, this system uses a high-strength chain to handle higher torque loads. It is better suited for larger vehicles and SUVs that require stronger power delivery. The design enhances durability under demanding driving conditions.

3. Toric CVT:

Uses rotating discs and rollers instead of belts or chains to transfer torque. It is capable of handling heavy loads and high-torque applications. However, its complexity and cost limit its widespread use in passenger vehicles.

4. Cone CVT:

Operates using friction between conical surfaces to vary gear ratios. While mechanically innovative, it is less common in modern passenger cars due to efficiency and durability limitations. It is mostly seen in experimental or niche applications.

5. e-CVT:

Electronically controlled CVTs are typically found in hybrid vehicles such as the Toyota Prius. They use a planetary gear system combined with electric motor control instead of traditional belts. This setup enhances fuel efficiency and ensures seamless power blending between engine and motor.

Types are chosen by manufacturers depending on power requirements and expense.

CVT vs. Traditional Automatic Transmission in Cars

CVT transmission differs from conventional automatics in key ways:

| Feature | CVT | Traditional Automatic |

|---|---|---|

| Gears | Infinite ratios | 4-10 fixed gears |

| Shifting | Seamless | Noticeable steps |

| Efficiency | Higher mileage | Moderate |

| Cost | Lower upfront | Higher |

| Feel | Rubber-band effect | Firm shifts |

Key Advantages of CVT in Cars

CVT offers practical benefits for daily drivers:

Fuel savings: Maintains ideal engine RPM, boosting mileage by 8 to 9%.

Smooth acceleration: No gear hunting in hills or traffic.

Compact design: Lighter than automatics, improves handling.

Lower emissions: Optimises power for eco-compliance.

Affordable: Cheaper to produce than dual-clutch systems.

Disadvantages of CVT in Cars

Despite its strengths, CVT transmission has limitations:

Rubber-band feel: Engine revs rise without speed gain initially.

Heat buildup: Prolonged strain overheats belts, risking failure.

Repair expense: Belt replacement costs ₹1-2 lakh after 60,000 km.

Less engaging: Lacks paddle-shift sportiness.

Torque limits: Suited to engines under 150 Nm.

How to Maintain a CVT Transmission in Cars?

Regular care extends the transmission life:

Change the CVT fluid every 40,000 km with manufacturer-spec oil.

Avoid aggressive launches or towing beyond limits.

Monitor for slipping, whining noises, or warning lights.

Use premium fuel to reduce carbon buildup.

Service is available at authorised centres for warranty validity.

Proper maintenance cuts breakdown risks, which is important for car insurance online claims.

How to Efficiently Drive a CVT Car?

Driving habits maximise CVT benefits:

Accelerate slowly to minimise belt stress.

Use eco or drive modes for city commutes.

Instead of braking abruptly, stop gently.

Anticipate traffic for predictive ratio changes.

Park on flats to ease startup loads.

These practices enhance mileage and longevity.

Summary

CVT in cars offers smooth, fuel-efficient driving with seamless gear shifts and lower emissions, making it ideal for daily use. While it has some limitations like the rubber-band feel and torque constraints, proper maintenance and careful driving can extend its life and performance. Understanding CVT features also helps make informed choices for car insurance and long-term ownership.

Related Articles:

What Is AMT in Cars and How Does It Work?

Types of Car Transmissions: How Does it Work?

Manual vs. Automatic Transmission Cars

FAQs on CVT in Cars

Why is CVT called a stepless transmission?

CVT earns the 'stepless' label due to its infinite gear ratios via pulley adjustments, eliminating fixed gear jumps. Drivers experience unbroken power delivery. This design suits stop-and-go driving.

Which transmission is good for mileage, manual or CVT?

CVT transmissions often edge manuals in mileage by holding optimal RPM, claiming 20–25 km/l in models like the Honda Amaze. Manuals suit highways. Real-world results vary by driving style.

What should be noticed when buying a used CVT car?

Inspect service history for fluid changes, check for jerking or overheating signs, test drive for smooth response, verify warranty status, and review repair records. High-km units risk belt failure.

Is it difficult to drive a CVT car?

No, CVT cars drive like standard automatics with intuitive pedal response. New drivers adapt quickly. Paddle shifters add control in premium variants.

Does CVT in a car mean automatic?

Yes, CVT functions as an automatic transmission without manual input. It automates all shifts.